There are two different methods for installing waterproofing membranes: flame-baked (also known as hot melt) and self-adhesive. So, what’s the difference between flame-baked and self-adhesive waterproofing membranes? Let’s discuss them in detail.

Burned Waterproofing Membrane Installation

Differences Between Flamed and Self-Adhesive Waterproofing Membrane

1. Material Composition

Modified asphalt (SBS) waterproofing membranes make burned waterproofing membranes. Polyester felt, fiberglass felt, or fiberglass-reinforced polyester felts serve as the carrier, while styrene-butadiene (SBS) thermoplastic elastomer acts as the asphalt modifier, and double-sided insulation material completes the construction.

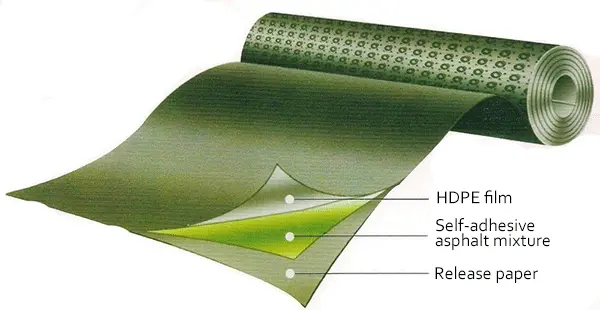

Self-adhesive waterproofing membranes, on the other hand, are constructed with a self-adhesive rubberized asphalt base, made from a synthetic rubber like SBS, a tackifier, and high-quality road asphalt. They have a tough high-density polyethylene film or aluminum foil as the top surface, and a removable silicone-coated release film or paper as the bottom surface.

2. Different Construction Techniques

For fire-baked waterproofing membrane, first clean the base surface and apply a base coat. Then, lay the membrane flat, cut it to the desired size, and roll it up. Light a gas can and begin heat-melting the membrane as you lay it down, ensuring a tight seal.

Self-adhesive waterproofing membrane, on the other hand, requires less effort. Simply remove the barrier layer and slowly lay it down until it firmly adheres to the base.

3. Different Performance

Fire-baked waterproofing membrane offers excellent corrosion resistance and durability, as well as excellent elasticity and low-temperature waterproofing. It also exhibits excellent fatigue and crack resistance.

Self-adhesive waterproofing membrane, on the other hand, offers excellent low-temperature flexibility, self-healing properties, and adhesion, making it quick to install and environmentally friendly.

4. Different Applications

Fire-baked waterproofing membrane is suitable for exterior waterproofing, whether it’s a building roof or underground parking lot, or any rooftop, basement, reservoir, swimming pool, or similar.

Self-adhesive waterproofing membrane is primarily used on smooth, flat roofs, such as metal and glass roofs. It’s a good choice for applications like prefabricated steel buildings and sunrooms. The above is the difference between fire-baked waterproof membrane and self-adhesive waterproof membrane. You can apply the two types of membranes according to the applicable scope of the location where you want to use them. If you have any questions or needs in this regard, please contact us to improve the waterproofness and durability of the building.

Contact Us

For more information or to inquire about our waterproof floor paint solutions, feel free to get in touch with us. We’re here to help!

- Phone: +86 138 6365 6701

- Email: Huafengwaterproof@gmail.com

- WhatsApp: +86 138 6365 6701

We look forward to assisting you with all your waterproofing needs!