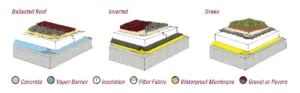

TPO, PVC, and EPDM are popular single-ply roofing membranes, each with distinct properties suited to different roofing needs.

Material Composition and Lifespan

-

EPDM is a synthetic rubber thermoset material known for flexibility and durability, especially in cold climates, with lifespans typically between 20 to 40 years.

-

TPO (Thermoplastic Polyolefin) is a thermoplastic membrane made from polypropylene and ethylene-propylene rubber, offering good flexibility and moderate lifespan around 15–25 years.

-

PVC (Polyvinyl Chloride) is a thermoplastic membrane with excellent durability and chemical resistance, often lasting 25–30 years or more, with some formulations lasting up to 40 years.

Seaming and Installation

-

TPO and PVC membranes use heat-welding for seams, creating strong, watertight joints that can expand and contract with building movements.

-

EPDM relies on adhesives or seam tapes, making seams less durable and potentially more prone to aging and failure over time.

UV, Heat, and Chemical Resistance

-

EPDM has excellent UV resistance due to carbon black content but absorbs heat due to its black color, which can increase building cooling costs.

-

TPO is highly reflective and reduces heat absorption but can lose reflectivity and degrade with chemical exposure over time, especially in polluted or industrial environments.

-

PVC has superior chemical resistance and fire retardant properties, making it suited for harsh chemical environments and commercial roofs like restaurants and airports.

Cost and Energy Efficiency

-

TPO typically has the lowest material cost among the three.

-

EPDM is moderately priced and offers great flexibility but has less reflective properties unless coated.

-

PVC is the most expensive but provides long-term durability and energy savings with its high reflectivity and chemical resistance.

Summary Table

| Feature | TPO | PVC | EPDM |

|---|---|---|---|

| Lifespan | 15–25 years | 25–30+ years | 20–40 years |

| Seaming | Heat-welded (strong) | Heat-welded (very strong) | Adhesive/tape (moderate) |

| UV Resistance | Good, reflective | Excellent | Very good, but less reflective (black) |

| Chemical Resistance | Good | Excellent | Fair |

| Cost | Low–moderate | Moderate–high | Low–moderate |

| Flexibility | Good | Moderate | Excellent |

| Energy Efficiency | High (reflective white) | High (reflective white) | Low (black, unless coated) |

Recommendations

-

Choose EPDM for cold climates, flexibility, and budget-friendly solutions when black roofing is acceptable.

-

Choose TPO for affordability, good energy efficiency, and moderate durability in less chemically harsh environments.

-

Choose PVC for longer lifespan, superior chemical resistance, fire resistance, and commercial/industrial applications needing high durability.

Regular maintenance and quality installation are critical to all three types for maximizing roof lifespan and performance.